Integrirani tehnički servisi izgradnje postrojenja u RH i u inozemstvu.

About the company

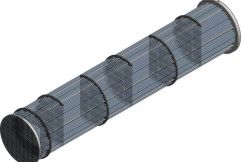

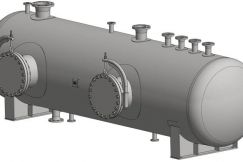

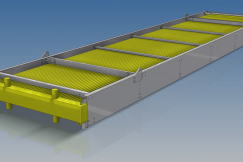

Manufacturing of equipment and spare parts

STSI is certified, in accordance with the HRN EN ISO 3834-2 standard, for manufacturing and installation of pipelines and pressure vessels of category II, III and IV.

Manufacturing plants in Zagreb and Graberje Ivanićko consist of manufacturing workshops with a surface area of 3500 m2, with four industrial cranes with a capacity of 2-20 t.

Scope of works is as follows:

• Manufacture of lightweight and heavyweight steel structures

• Manufacture and installation of pipelines

• Rehabilitation of existing pipelines

• Manufacture of underground and above-ground drilling equipment

Applicable materials in accordance with the ASME and EN standards:

• carbon steel

• carbon steel for low and increased temperatures

• low-alloy steel for increased temperature

• high-alloy steel

• copper-titanium alloys

Specialist staff at the sites are the following:

• three EWE engineers

• eight engineers in manufacture preparation

• 20 welders

• 9 pipefitters

• 20 machinists

Some of the machines used by STSI in manufacturing the equipment are the following:

• automatic ESSAB SAW welding machine

• sheet metal bending machine for thickness up to 50 mm

• CNC machining centre

• CNC press brake for angular bending of sheet metal

• CNC plasma/gas cutting machine

• hydraulic scissors

• TIG, MMA, MIG/MAG welding machines

• classic and CNC lathes

• machine park with thirty devices for machining