Integrirani tehnički servisi izgradnje postrojenja u RH i u inozemstvu.

About the company

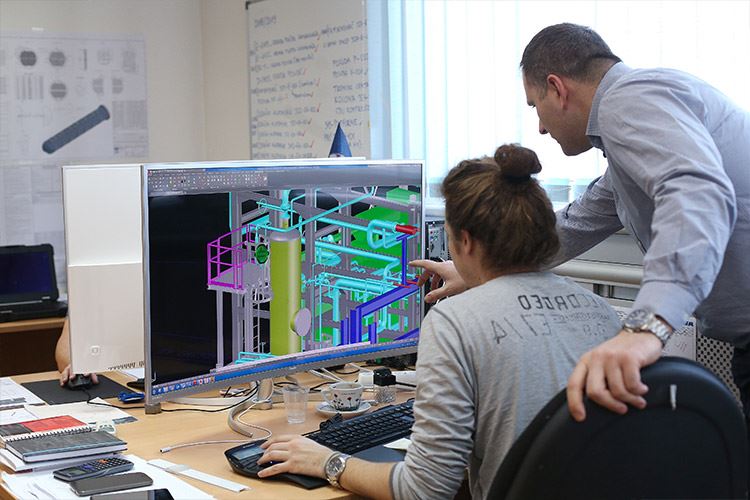

Engineering and Design

STSI performs works on construction and reconstruction of facilities and plants in the Republic of Croatia and abroad.

In the Republic of Croatia, STSI has, independently or as a consortium partner, taken part in the following construction or reconstruction projects:

- Refinery plants

- Reconstruction of hydrant network system at Rijeka Refinery

- Construction of a water barier container 320-V-002 and vessel reconstruction 320-V-051 at Rijeka Refinery (Flare Gas Recovery System)

- Revitalization of the extinguishing and cooling system of the D Group of tanks at Rijeka Refinery

- Construction of a system for monitoring the consumption of energy media at Rijeka Refinery

- Construction of a system for enhancing energy efficiency of the atmospheric distillation plant at Rijeka Refinery

- Construction of a system for optimization of hydrogen consumption and production at Rijeka Refinery

- Tank 333-SC-019 Reconstruction at Rijeka Refinery

- Tank 333-SC-018 Reconstruction at Rijeka Refinery

- Construction of hydrocracking interconnecting pipelines at Rijeka Refinery

- Construction of solar power plants at the SPP (Solar Power Plant) Virje and SPP Sisak sites

- Reconstruction of the tank wagon depot at Sisak Refinery

- Construction of the PSA 2 plant at Sisak Refinery

- Construction of the Clus plant at Sisak Refinery

- Construction of the biofuel system at Sisak Refinery

- Construction of the PENEX low-temperature isomerization plant

- Reconstruction of the plant for hydrodesulfurization of petrol and diesel fuel (L/LCh – engineering, procurement, construction supervision and commissioning (EPS)

- Construction of the CLAUS plant for the production of the elemental sulfur, phase I – engineering, procurement, construction supervision and commissioning (EPS)

- Construction of the CLAUS plant for the production of elemental sulphur, phase II – engineering, procurement, construction supervision and commissioning (EPS)

- Oil and gas exploitation plants

- Construction of well sites at INA fields

- Međimurje project – connecting gas pipeline and facilities of the Vučkovec field

- Construction of gas processing plant at MDS (Metering and Dispatch Station) Đeletovci

- Construction of compressor station at the CGS (Central Gas Station) Molve

- Revitalization of existing pipelines by inserting composite pipes

- Reconstruction of the main pipeline Sisak – Virje – Gola

- Reconstruction of the aMDEA system at the CGS (Central Gas Station) Molve 3

- Installation of cogeneration turbine blocks TEA 3 and TEA 4 at CGS Molve

- EOR (enhanced oil recovery) project – construction of CO2 injection system

- Palmyra Project – construction of a well gathering system, gas station, gas pipeline – engineering, procurement and construction supervision

- Jazal Project – construction of a well site and gas pipeline – engineering, procurement and construction (EPC)

- Jihar Project Stage 2 – construction of a well gathering system, gas treatment plant with a compressor station – engineering, procurement and construction (EPC)

- LNG Terminal, Omišalj, Croatia

- Construction of jetty, auxiliary facilities and plant for the LNG Terminal Omišalj, Krk

- Gas pipelines

- Pula – Karlovac gas pipeline

- Offshore plants

- Construction of the supporting structure (jacket) of Ivana K platform

- Modification of Ika A, Ida C, Ivana K, Ivana E and Katarina platforms

Design

STSI d.o.o. provides design services focused on the design of new and reconstruction of existing plants in the oil and gas industry:

- design of tanks and pipelines

- equipment design

- design of all types of steel and concrete structures

- design of electrical and instrumentation systems

Highlighted projects

- Preparation of design documentation for the reconstruction of spherical tank 336-SE-023 and interconnecting pipelines at RR

- Preparation of design documentation for manufacture of hydraulic pipe lifter

- Preparation of design documentation for the reconstruction of cylindrical tanks with a capacity of up a 80,000 m3

- Preparation of design documentation for the project of installing a portable compressor unit at the GS (Gas Station) Gola Duboka in the hydrocarbon exploitation field

- Preparation of design documentation for the repair of concrete structures of the sump area (bunding) for the tank 331-SA-018/019/020 at RR (Rijeka Refinery)